I didn't get my engine assembled before my holiday to China, so I have something to look forward to when I get back.

If you are interesseted, and can read danish, you can follow my travel blog at http://emil-i-kina.blogspot.com/.

If not, then you can look forward to new and exciting stuff, as I return in may.

Sunday, March 16, 2008

Thursday, March 6, 2008

Catch up

I have been quite busy, so here is a quick catch up on the project.

While I have been waiting for the OEM parts, I have been busy sanding down my fairing and the tank as preparation for some paint. It is tedious and time consuming, but I hope the end result will be worth it.

I have also removed the rear swing arm, to clean it and lube the bearings.

The Yamaha OEM parts arrived Friday, and everything was okay, except for the crankshaft bearings. The bearings I received are the tightest ones, and I need the loosest ones. The dealer promised to ship them express, so I hope they will arrive before my holiday.

Quick list of things I have done:

A mold of an intake port.

Refurbished the water pump.

Assembled the cylinder head.

Checked and adjusted the valve clearance.

Changed the gearbox bearings.

Cleaned and installed the gearbox.

Changed the strainer on the oil pickup.

I have photos and detailed descriptions coming real soon now.

While I have been waiting for the OEM parts, I have been busy sanding down my fairing and the tank as preparation for some paint. It is tedious and time consuming, but I hope the end result will be worth it.

I have also removed the rear swing arm, to clean it and lube the bearings.

The Yamaha OEM parts arrived Friday, and everything was okay, except for the crankshaft bearings. The bearings I received are the tightest ones, and I need the loosest ones. The dealer promised to ship them express, so I hope they will arrive before my holiday.

Quick list of things I have done:

A mold of an intake port.

Refurbished the water pump.

Assembled the cylinder head.

Checked and adjusted the valve clearance.

Changed the gearbox bearings.

Cleaned and installed the gearbox.

Changed the strainer on the oil pickup.

I have photos and detailed descriptions coming real soon now.

Thursday, February 14, 2008

Short up

A quick picture of my new short stub exhaust. It was quite easy. I drilled out the rivets and pulled the intake end cap out. The inner pipe is attached to the intake end cap, so it came out as well. The can is filled with glass wool, so be smart (unlike me) and wear some good gloves, else you can look forward to two days of itching hands. Once I had the can disassembled, I took the angel grinder to both the can and the inner pipe. After that I assembled the short can, and drilled holes for the new rivets. Some riveting later, and presto! A new fanzy short stub Akapovic end can.

Wednesday, February 13, 2008

Up close

Camera galore

Yeasterday I celebrated my 29th birthday by buying a camera. I went with a Canon Ixus 75, since they are quite cheap, and in the past I have been pleased with the Ixus 50 and Ixus 55 models. They are easy to handle and take nice pictures, their only flaw is that I tend to forget them in trains and parks. I hope this camera will last a little longer than the last two in that respect.

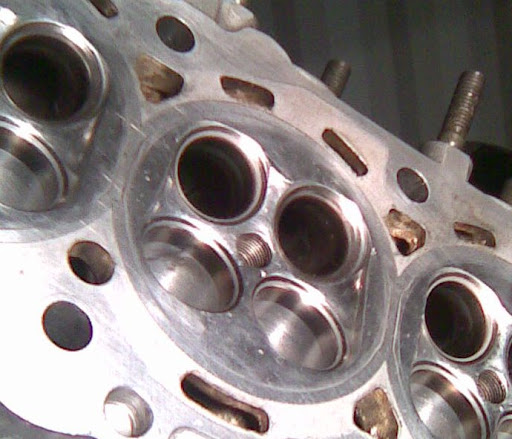

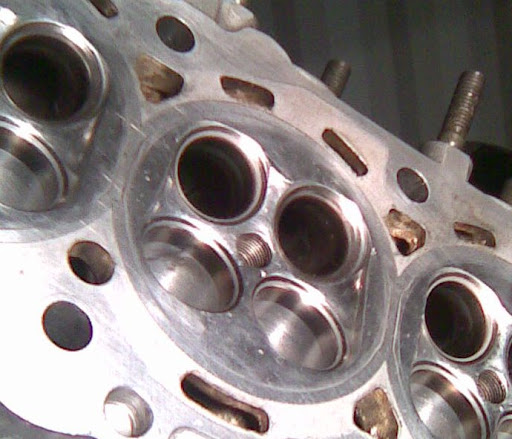

My new camera was put to good use immidiatly. First up is some pictures of the newly polished pistons. The polishing revealed just how much the valves have been touching the pistons, especially piston nr. 2 have had a lot of contact with the exhaust valves, as can be seen on this closeup.

My new camera was put to good use immidiatly. First up is some pictures of the newly polished pistons. The polishing revealed just how much the valves have been touching the pistons, especially piston nr. 2 have had a lot of contact with the exhaust valves, as can be seen on this closeup.

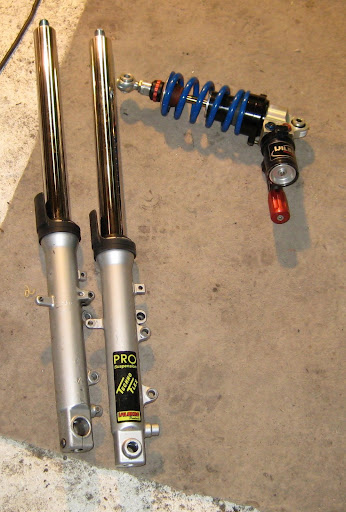

I also took the time to pull the suspension, both the rear shock and the front forks. I am sending them to Michael Graversen at Hyperpro so he can give them a full maintanence. I need a new and softer spring for the rear shock, and new springs for the front. Michael will also give them a cleaning, new oil and new oil seals.

I also took the time to pull the suspension, both the rear shock and the front forks. I am sending them to Michael Graversen at Hyperpro so he can give them a full maintanence. I need a new and softer spring for the rear shock, and new springs for the front. Michael will also give them a cleaning, new oil and new oil seals.

Wednesday, February 6, 2008

Bling Bling!

My polishing spree continued this week, and I polished one of the pistons to a mirror finish. I figured it would be a good idea, and well, frankly it just looks damn good.

My polishing spree continued this week, and I polished one of the pistons to a mirror finish. I figured it would be a good idea, and well, frankly it just looks damn good.I did a search on Speed Talk to see if there is any performance gains with a polished piston/combustion chamber. The consensus seems to be that there is no benefit in polishing, but it won't hurt either. This thread has an indepth discussion of the topic.

I also lapped the valves. This took some time, but I am sure it will make a difference. The exhaust valves was quite pitted, and they must have been leaking a bit. The intake valves was in much better shape, but their seats was pitted. I guess the reason for this pattern is the difference in temprature. The exhaust valves get quite a bit hotter than the intake valves, and that is the reason why they pit, while the intakes doesn't.

Left is a lapped and unlapped valve, my cameraphone won't take good enough pictures to show the pitting on the unlapped valve, but it is quite obviuos when you have it in your hand.

Left is a lapped and unlapped valve, my cameraphone won't take good enough pictures to show the pitting on the unlapped valve, but it is quite obviuos when you have it in your hand.

I had to lap the exhaust 2-3 times with the coarse lapping compund, and then finish them with one lapping with the fine compund. The intakes was easier and only required one time with each compund.

I also lapped the valves. This took some time, but I am sure it will make a difference. The exhaust valves was quite pitted, and they must have been leaking a bit. The intake valves was in much better shape, but their seats was pitted. I guess the reason for this pattern is the difference in temprature. The exhaust valves get quite a bit hotter than the intake valves, and that is the reason why they pit, while the intakes doesn't.

Left is a lapped and unlapped valve, my cameraphone won't take good enough pictures to show the pitting on the unlapped valve, but it is quite obviuos when you have it in your hand.

Left is a lapped and unlapped valve, my cameraphone won't take good enough pictures to show the pitting on the unlapped valve, but it is quite obviuos when you have it in your hand.I had to lap the exhaust 2-3 times with the coarse lapping compund, and then finish them with one lapping with the fine compund. The intakes was easier and only required one time with each compund.

Friday, February 1, 2008

Dirty shine.

My love for engine work has tanken a back seat the last few days. The doesn't mean I haven't been burning gasoline thou!

Last weekend I was out having fun with my Moto trials bike. I spent a few hours in storming rain on muddy hills, in deep trenches and got covered in mud as a reward.

Some of the guys had the new 4 stroke trial bikes, they look to be a very nice upgrade. So much easier to climb hills with them, just twist the throttle and go, no need to keep the engine up in the rew range.

Tuesday I was out having fun at the gocart track. Loads of fun, but the skills required to go fast is very different from what I use when I roadrace, I really have a lot to learn there.

When not burning gasoline, with or without oil, I have been polishing the cylinder head and the pistons. I don't know how effective this will be, but it sure looks good.

I have also been removing all of the carbon deposits on the valves, and there were a lot on them. The deposists at the bottom looked light brown, and I think that indicates that the engine has run on race gas. That would explain the very low AF ratio I got when I had the bike on the Dyno.

Last weekend I was out having fun with my Moto trials bike. I spent a few hours in storming rain on muddy hills, in deep trenches and got covered in mud as a reward.

Some of the guys had the new 4 stroke trial bikes, they look to be a very nice upgrade. So much easier to climb hills with them, just twist the throttle and go, no need to keep the engine up in the rew range.

Tuesday I was out having fun at the gocart track. Loads of fun, but the skills required to go fast is very different from what I use when I roadrace, I really have a lot to learn there.

When not burning gasoline, with or without oil, I have been polishing the cylinder head and the pistons. I don't know how effective this will be, but it sure looks good.

I have also been removing all of the carbon deposits on the valves, and there were a lot on them. The deposists at the bottom looked light brown, and I think that indicates that the engine has run on race gas. That would explain the very low AF ratio I got when I had the bike on the Dyno.

Subscribe to:

Posts (Atom)